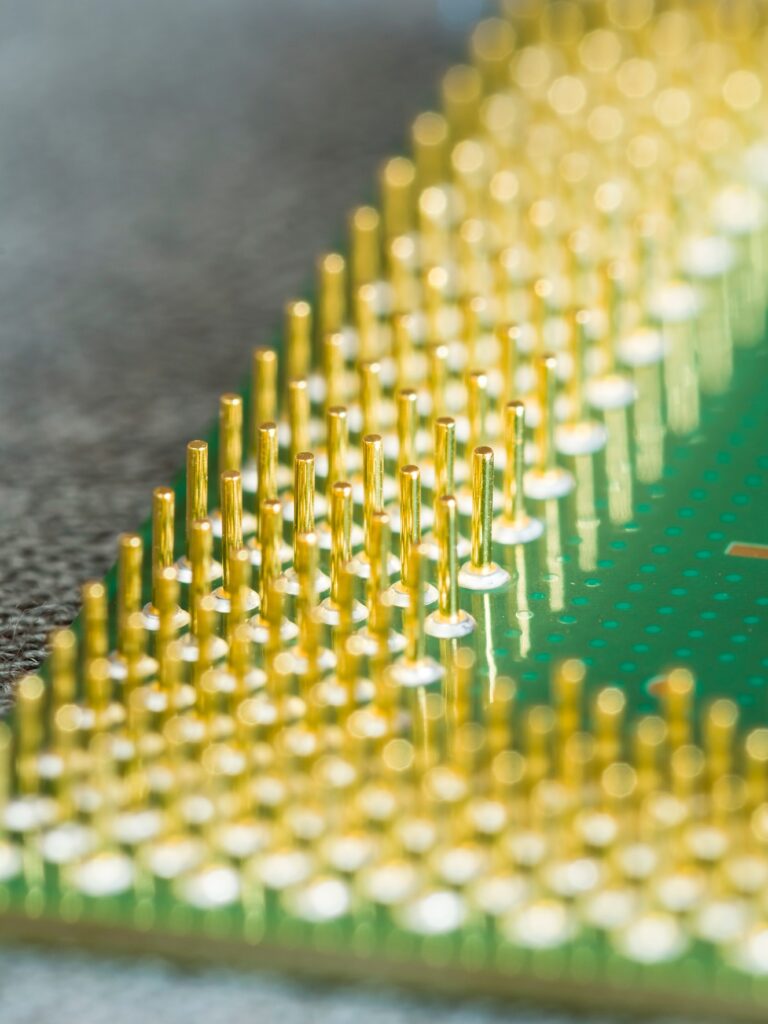

In semiconductor manufacturing, dimensional accuracy at the micron and sub-micron level is critical to every stage of the process. Hour Precision supports equipment manufacturers and R&D groups with ultra-precise components for wafer handling, alignment, vacuum interface hardware, and thermal management structures. Our expertise spans the machining of high-stability parts used in lithography systems, metrology stages, probe cards, and electrostatic chucks, where flatness, parallelism, and positional repeatability directly affect chip yield. We also manufacture custom fixtures and tooling for mask alignment, wafer bonding, and high-aspect-ratio part handling. With capabilities that include tight-tolerance machining in aluminum, stainless steel, titanium, PEEK, and ceramic-compatible substrates, we help our clients maintain process control at nanometer scales. In a field where a micron off means failure, Hour Precision delivers with consistency few others in North America can match.

As device geometries shrink and process nodes tighten, micro machining plays a critical role in enabling mechanical components that can meet the extreme precision, cleanliness, and stability demands of semiconductor fabrication. Hour Precision delivers ultra-fine features, sharp edge definitions, and complex geometries in components such as wafer grippers, precision bushings, fluid delivery manifolds, and alignment hardware used in lithography, etch, and CMP systems. Our ability to machine tight-radius internal features, high-aspect-ratio slots, and vacuum-compatible microstructures with sub-5 micron tolerances helps reduce mechanical-induced variation, improve part life under repetitive motion, and maintain system performance over extended duty cycles. For OEMs and toolmakers pushing the limits of yield and uptime, we provide the machined precision infrastructure their platforms depend on.

Applications in Semiconductors

We manufacture ultra-precise components for wafer handling, process chambers, and thermal systems used in advanced semiconductor fabrication.

- Wafer Handling & Transport

- Vacuum & Process Chambers

- Thermal Management Assemblies

- Alignment & Positioning Mechanisms

- Custom Tooling & Fixtures